Commercial swimming pool heat pumps, as essential equipment for pool heating and temperature maintenance, have seen increasing application in the pool sector in recent years. They operate on the same principle as ordinary heat pumps, by absorbing heat from the air and transferring it to the pool water through processes such as compression and heat exchange, thereby heating the pool water and maintaining a constant temperature. This type of equipment is particularly suitable for commercial pools that require long-term, large-scale water heating.

Installation and Operation of Commercial Swimming Pool Heat Pumps

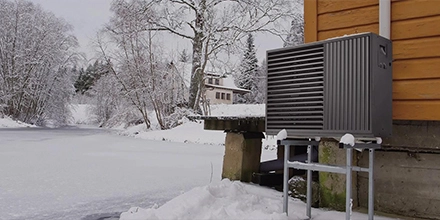

The installation of commercial swimming pool heat pumps is divided into two parts: the installation of the heat pump unit and the installation of the pool water system. The heat pump unit must be installed within 6 meters of the pool in a clean, well-ventilated location, and a base above 25cm must be constructed. To reduce machine vibration, be sure to install vibration dampers and fix the base with screws; for top-blow units, maintain a distance of more than 2 meters between the air inlet and the top, and for side-blow units, keep at least 1 meter between the air inlet and the wall; when multiple units are installed simultaneously, keep a distance of more than 1 meter between units.

When the commercial swimming pool heat pumps are in operation, condensate will form on the evaporator fins and drip onto the base (note, this phenomenon might be mistaken for a heat pump leak, but it is normal); thus, a drainage pipeline needs to be installed on the base to facilitate condensate discharge. In addition, a drainage system should be set up around the unit to prevent the risk of unit flooding during the rainy season.

In the entire pool water system, the heat pump should be installed upstream of all ozone generators, chlorine generators, chemical disinfection equipment, etc., and downstream of all filtration devices and pool pumps. It is recommended to wrap all pipes with 10mm thick insulation material to prevent heat loss from the pipes during windy and cold seasons, which would increase the heating load on the unit.

When installing the pool water system, try to shorten the water pipeline as much as possible and reduce or avoid unnecessary pipe turns to reduce resistance loss. Install an air release valve at the highest point of the main water pipe to purge air from the system when it is present; install a drain valve at the lowest point of the entire water system to facilitate drainage during system cleaning. The insulation performance of the water tank system should be good and it should be kept away from corrosive gases or liquids; do not connect tap water pipes or other water pipes to the circulation pipeline to avoid damage to the circulation pipeline and the heat pump unit; select a water pump with suitable flow and head to ensure that the water flow meets the unit's requirements.

How to Maintain and Care for AXEN Commercial Swimming Pool Heat Pumps?

During the use of commercial swimming pool heat pumps, only good daily maintenance and care can ensure their durability and extend their service life. So, how should one maintain and care for pool heat pumps?

Regularly check whether the electrical system wiring in the control box of the pool heat pump is loose or if there are any anomalies in electrical components. Address and replace any issues promptly; frequently check whether all parts inside the unit are operating normally, whether there is any oil stain at the inflation valve, and whether there is any leakage at the water pipe joints; regularly check whether the instrument readings on the unit are normal and troubleshoot immediately in case of any abnormalities;

Regularly inspect the water system for leakages and ensure that all water pumps and valves are operating correctly. If the system is to be shut down for a long period, be sure to drain the water from the unit and water system, and disconnect the power supply. Before restarting the unit, perform a comprehensive inspection and test of the system.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Ελλάδα

Ελλάδα Polska

Polska Nederland

Nederland

.webp)